Updated 2 weeks ago

Solar panel efficiency explained: most efficient solar panels 2024

Written by

Catherine Lane

What is solar panel efficiency?

A solar panel’s efficiency rating tells you how good a solar panel is at turning sunlight into usable electricity. The higher the efficiency rating, the more electricity that panel can generate.

Today, most home solar panels have efficiency ratings between 19% and 21%. But as solar technology improves, more and more solar manufacturers are reaching 22% or higher efficiencies. For comparison, data from the National Renewable Energy Laboratory shows the average solar panel was only 14.1% efficient in 2010. Solar panel efficiency has changed over time, and we’ve come a long way!

22% efficiency might not seem that impressive - but most things don’t operate as close to 100% as you think. According to Penn State University, gasoline car engines are about 25% efficient, and power plants are just 36% efficient.

What are the most efficient home solar panels in 2024?

Maxeon offers the highest efficiency solar panels of 2024, with maximum efficiency ratings of 22.8%. That’s impressive! REC, whose Alpha Pure-RX models can reach 22.6% efficiency, is not far behind.

Here are the top five highest efficiency home solar panels:

Solar panel model | Efficiency rating |

|---|---|

SunPower Maxeon Residential AC 440 W | 22.8% |

REC Group Alpha Pure-RX 470 W | 22.6% |

Jinko Eagle G6 440 W | 22.53% |

Heliene 108 HC M10 TPC SL | 22.49% |

Yingli Panda 3.0 Pro | 22.28% |

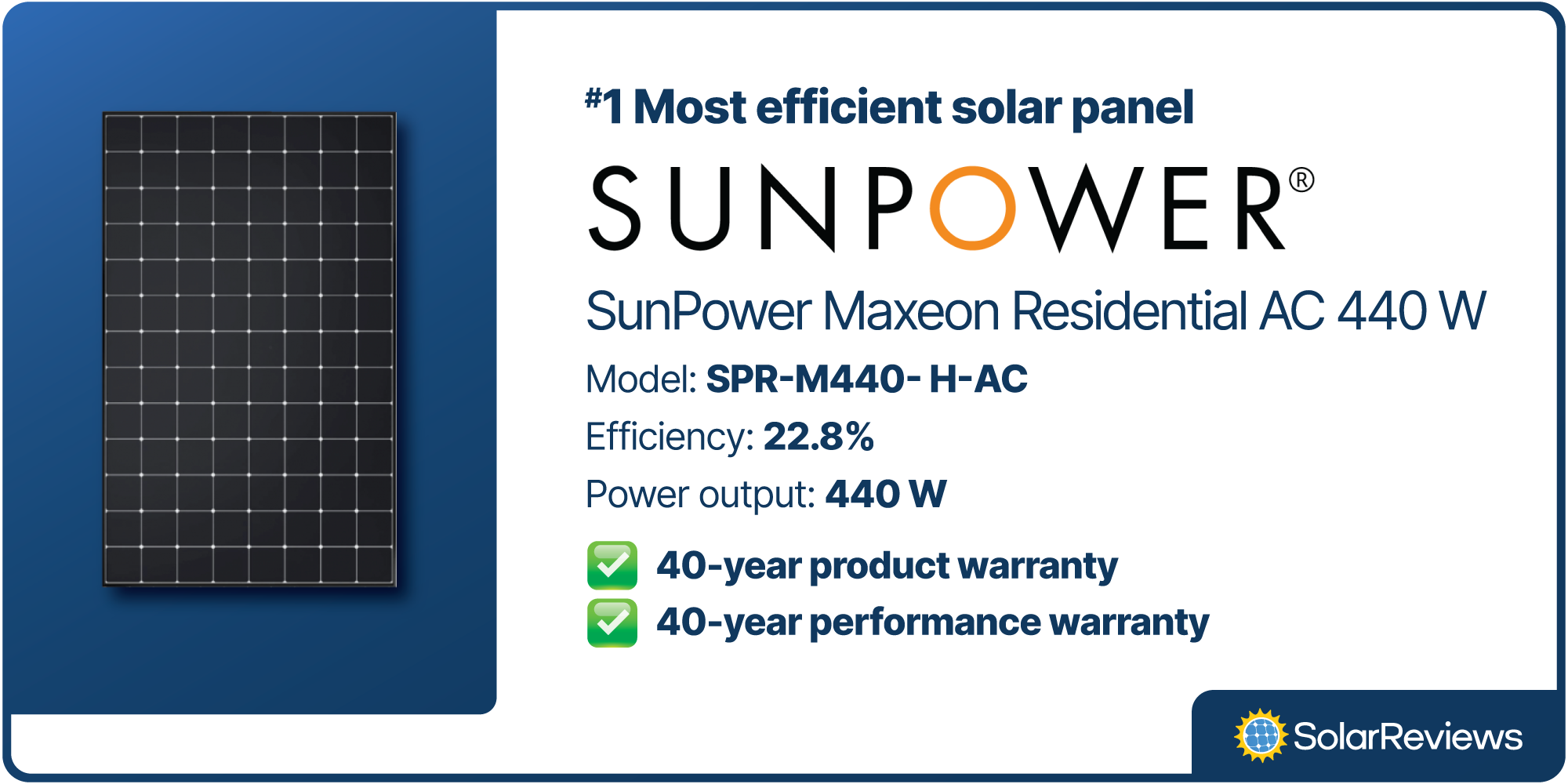

1. SunPower Maxeon Residential AC 440 W

Maxeon’s SunPower Residential AC 440 W residential model takes first place as the most efficient residential home solar panel. Maxeon has been using the same technology it patented in 2005, keeping it a top maker of high-efficiency solar panels for years.

The combination of Maxeon’s patented interdigitated back contact technology, high-quality silicon, and an integrated microinverter on the back of each Maxeon AC panel has allowed the company to reach efficiencies of 22.8%.

Although Maxeon manufactures the solar panels, they are only available through SunPower dealers. But, other high-quality Maxeon models can be purchased through non-SunPower companies.

Read more about what our solar experts have to say in our full Maxeon solar panel review.

2. REC Group Alpha Pure-RX 470 W

The REC Alpha Pure-RX 470-watt panel has an impressive efficiency rating of 22.6%. In 2014, REC started using half-cut technology to improve the efficiency and performance of its panels. Ten years later, the company still uses it and is seeing fantastic results.

One Alpha PURE-RX model takes up 22.4 square feet, making it slightly larger than the size of a standard residential solar panel. The increased footprint makes the panel more powerful, so fewer need to be installed to produce enough power to run a home.

Use our expert review of REC to learn more about other high-efficiency panels the brand offers.

3. Jinko Solar Eagle G6 440 W

Jinko Solar’s new Eagle G6 440-watt solar panel is 22.53% efficient, making it the third most efficient solar panel for homeowners. Like many solar manufacturers, Jinko Solar adopted n-type TOPCon solar cells for the Eagle G6.

TOPCon technology reduces heat losses from recombination that occurs within solar cells. But the specifics of how electrons bounce around inside solar cells don’t matter to homeowners; what does matter is that TOPCon cells allow solar panels to generate more electricity out of the sunlight they capture.

Jinko is another huge name in the solar industry, and it’s spent a lot of time on research and development to reach such impressive results. Some of Jinko’s models, like the Tiger NEO Mono 60 HC, are 22.71% efficient. These models, however, aren’t available in the United States.

Read more: Expert review of Jinko Solar

4. Heliene 108 HC M10 TPC SL All Black 440 W

Heliene isn’t as popular as some other brands, but its 22.49% efficiency panels are not to be ignored. Another panel that uses TOPCon cells, Heliene’s 108HC TPC SL All Black Module, exceeds the performance of many panels on the market today.

Despite having less brand-name recognition than companies like Panasonic, Heiliene is a Tier 1 company producing powerful, quality solar panels.

5. Yingli Solar Panda 3.0 Pro 435 W

Yingli Solar has been in the industry since 1998, manufacturing solar panels for home, commercial, and utility projects. Yingli’s panels come at an affordable price, especially for their performance.

The Panda 3.0 Pro module series also uses TOPCon solar cells and a multi-busbar design to boost efficiency ratings to an impressive 22.28%.

How much do high-efficiency solar panels cost?

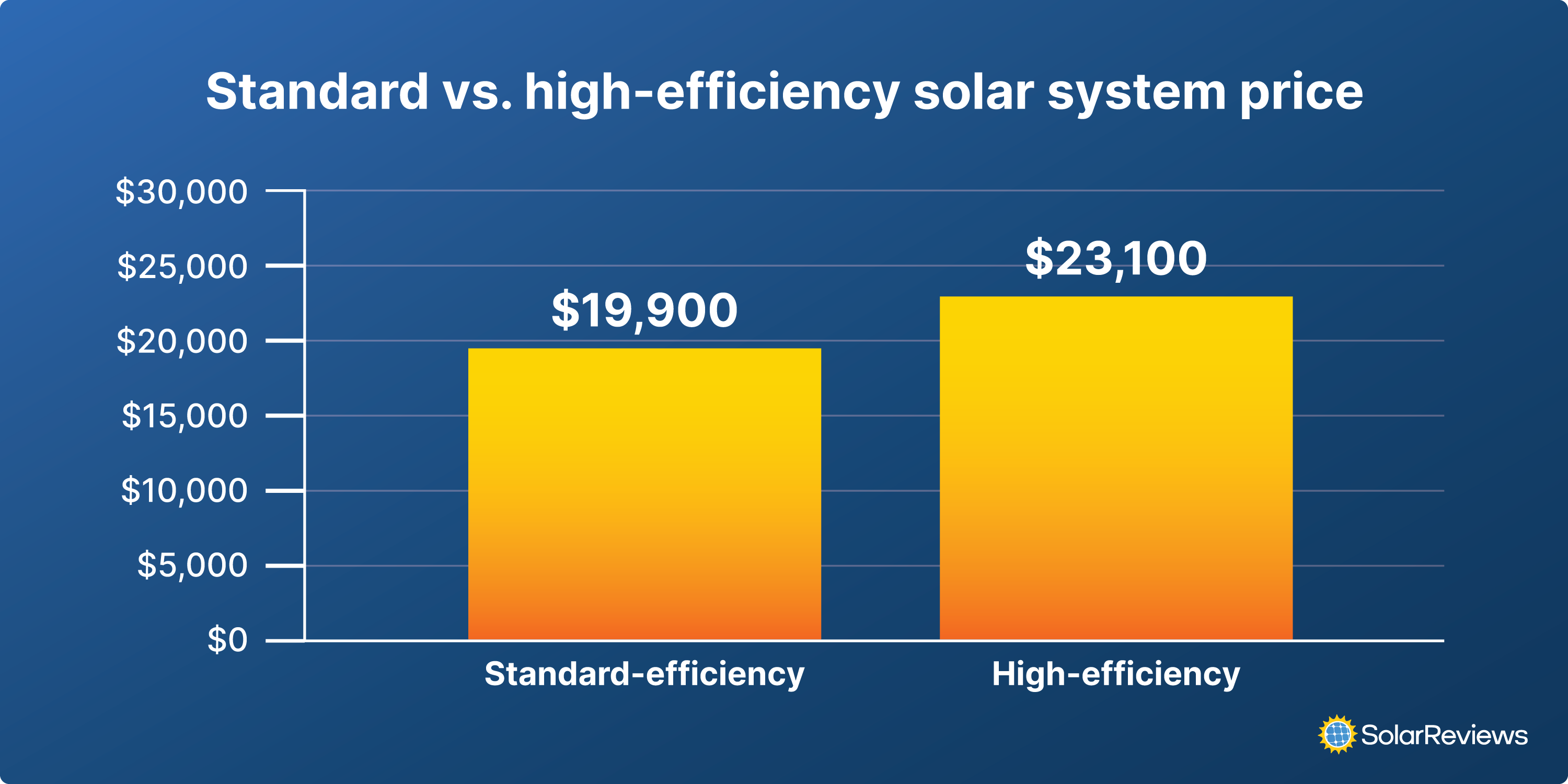

High-efficiency solar panels tend to come with a higher price tag and can add a premium of over $2,000 to the total cost of your system. That means a 7 kilowatt (kW) solar system using premium efficiency panels might cost around $23,100, while the same system using standard efficiency panels might be closer to $19,900.

But, the cost of highly efficient solar panels is getting lower, thanks to brands like Canadian Solar and LONGi. These companies are making great-quality panels with excellent efficiency ratings for a fraction of the cost of premium brands like SunPower. As these brands develop more products, efficiencies could rise while solar panel costs remain the same.

What impacts solar panel efficiency?

How efficiently a solar panel generates electricity is influenced by several factors, like the type of solar panel, the angle and direction in which it’s installed, and climate and weather conditions.

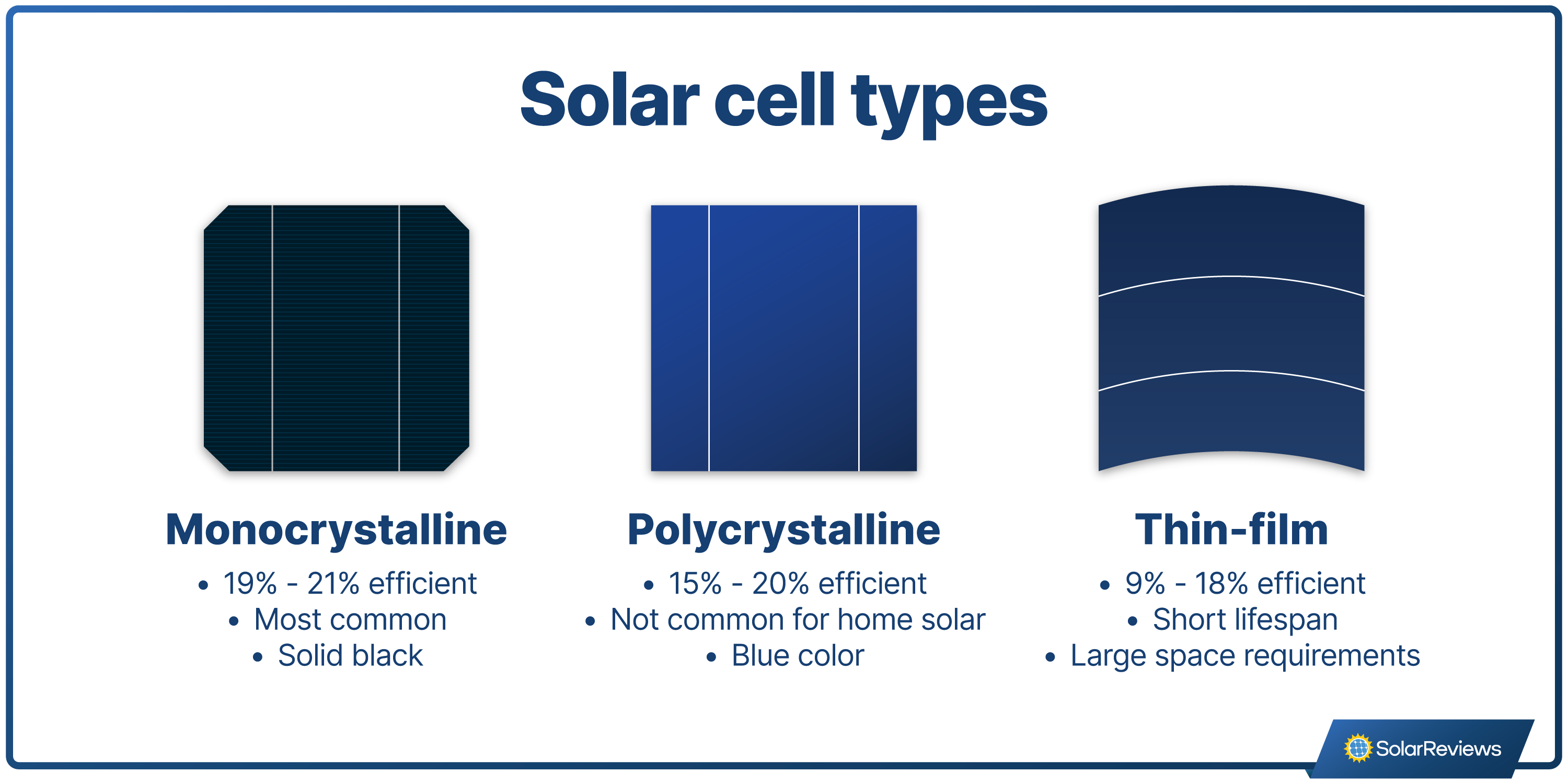

There are three main types of solar panels: monocrystalline, polycrystalline, and thin-film. However, almost every home solar installation uses monocrystalline panels because they’re the most efficient and look good!

Because monocrystalline solar panels are the most common, it’s important to understand the different technologies used in them that have made them even more efficient! Some of the most popular solar cells used today are Passivated Emitter and Rear Contact (PERC), Tunnel Oxide Passivated Contact (TOPCon), Heterojunction (HJT), and bifacial cells.

Solar technology is always evolving, so panels could be even more efficient in the next few years! One of the most promising new solar developments is perovskite solar cells, which could potentially reach an efficiency of 38%. But, perovskite panels won’t become mainstream until the price to manufacture them comes down.

Solar panel direction and angle

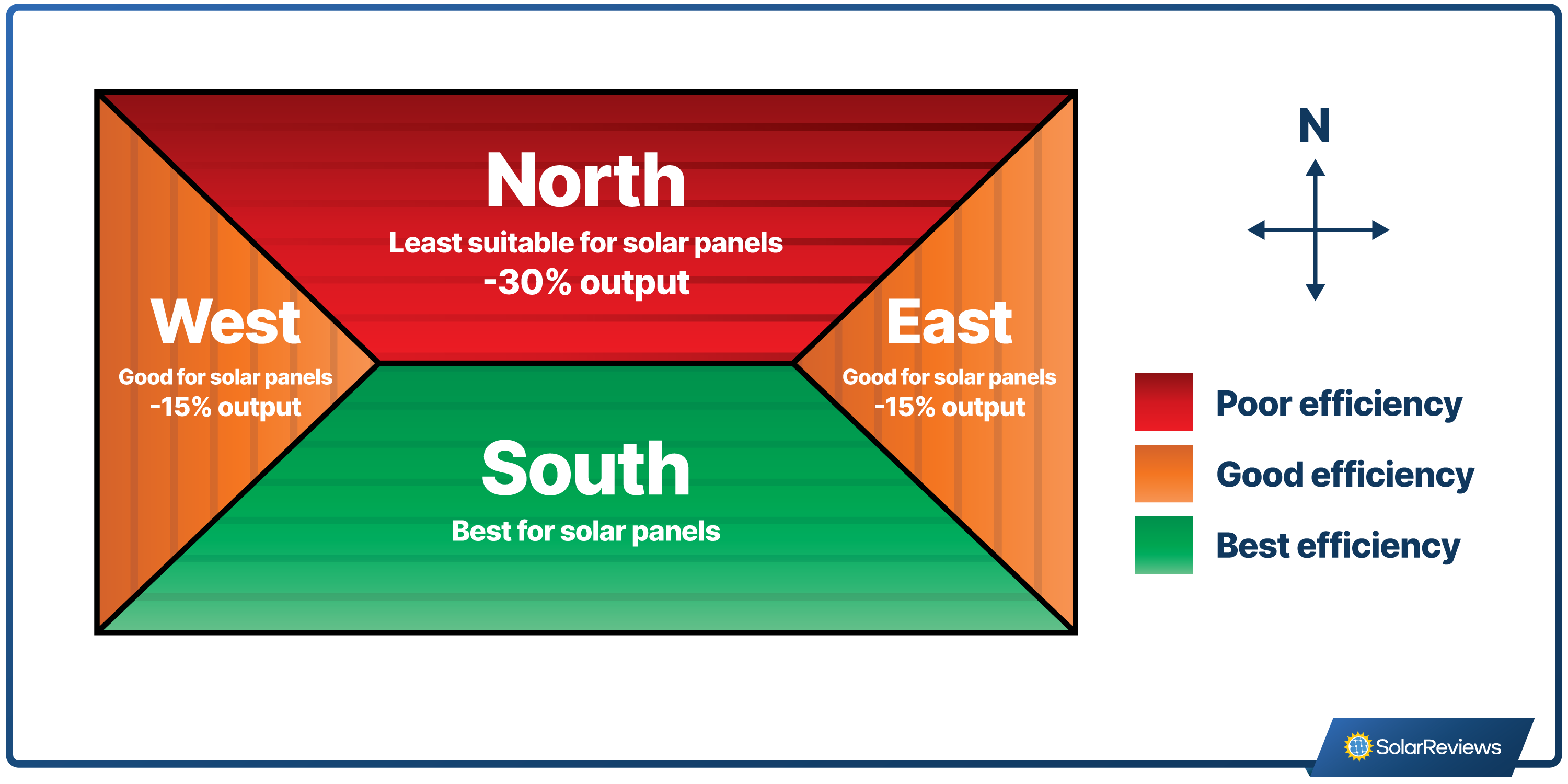

In the United States, solar panels generate the most electricity on south-facing roofs because the sun spends the most time in the southern sky. Solar panels installed facing west or east will still generate electricity, but they will be less than those installed towards the south.

The angle at which solar panels are installed can also make a difference. The ideal solar panel angle is based on the latitude of your home, so it varies by location. Solar panels are generally installed anywhere between a 20 and 45-degree angle for maximum solar energy generation.

Weather and climate conditions

The weather can impact how solar panels generate electricity. For example, solar panels that are covered with snow can’t generate electricity!

But, believe it or not, solar panels produce electricity more efficiently in colder temperatures! As the surface of a solar panel gets hotter, the efficiency drops slightly.

Cloud cover and shade can also cause solar panels to produce less energy. In general, though, these types of weather and climate conditions are taken into account by your solar installer when they design your system, so your panels will still generate the power you need!

How to increase your solar system’s efficiency

There are three steps you can take to keep your panels operating at their best:

Monitor your system’s performance: With solar monitoring software, you or your installer can keep tabs on your solar system’s performance. When an issue arises, you can address it right away!

Install panels on optimal roof space: Not everyone likes the look of solar panels. In fact, some homeowners opt to install them on the back of their house – but there might be better directions for solar panels than the back of your roof! If you want the most efficient system possible, ensure you get them where they’ll get maximum sun.

Keep them clean: Solar panels covered with dust or debris can’t generate electricity effectively. Make sure your solar panels are clear, and consider professional solar panel maintenance every year if your roof accumulates significant amounts of debris.

Your solar panels won’t operate at 100%! If your panels aren’t generating the same amount of electricity today as they were the day before, that’s okay! Solar panels don’t always yield the same amount of electricity, which is considered when the system is designed. You’ll know if there’s an issue if the entire system or sections of panels are offline or if you experience low output over an extended period

What else to consider when buying solar panels

The efficiency rating isn’t the tell-tale sign of a good solar panel. You’ll also want to check out the power output, which outlines how much power the solar panel can actually produce.

Another thing to consider is the solar warranties. Most solar panels today have a performance warranty of 25 years and a product warranty of 12 to 15 years. Anything less than that is a red flag.

The right panels for you also depend on the type of solar system you're installing. For example, if you're looking to go off-grid, you might want to spend a little more for premium efficiency to get the maximum amount of power possible.

Our solar experts also recommend getting panels from reliable manufacturers. Solar panels are a decades-long investment, and although solar panel failure is extremely rare, make sure you get panels from a manufacturer that will be around to honor the warranty. According to our 2022 Solar Industry Survey, the most common brands offered by installers were between Qcells and REC group.

Choosing the right installer is the most important step in going solar

What matters more than anything else when going solar is choosing the right solar installation company. At SolarReviews, we firmly believe that choosing the right solar installer is the key to getting the best solar system possible.

Good solar companies will have positive consumer reviews, won’t try to push you to get solar if you’re not ready, have been in business for at least five years, and employ certified, well-trained crews.

So, how do you find the best company near you? We can help. Using our solar calculator, you can discover how many solar panels you need and how much solar can save you on your electricity bills. Plus, we can get you in touch with trusted local solar companies in your area. Don’t worry - we never connect you

Methodology: How we found the most efficient solar panels

We reviewed solar panels offered by 28 brands and identified their most efficient residential solar panels. Residential solar panels were classified as panels that contained up to 66 cells or 132 half-cells.

If the company only had panels that exceeded this size limit, we used panels that the company classified as “residential”. Similarly, we did not include models with bifacial cells unless they were the only type of cell offered by the brand, such as REC Group’s panels.

Here is a complete list of the solar panels reviewed and their efficiency ratings:

Solar panel brand | Panel model | Efficiency rating |

|---|---|---|

Maxeon | SunPower/Maxeon 6 AC 440 W | 22.8% |

22.6% | ||

Jinko Solar | Eagle 54 G6R 440W | 22.53% |

Heliene | 108HC M10 TPC SL 440 W | 22.49% |

Panda 3.0 Pro 430 W | 22.28% | |

22.2% | ||

EverVolt EVPV410H | 22.2% | |

Silfab Prime NTC 430 W | 22.1% | |

SEG Solar | SEG Yukon N-Series 430 W | 22.02% |

VSUN (Vietnam Sunergy) | VSUN430N-108BMH | 22.02% |

Deep Blue 3.0 PRO 440 W | 22.0% | |

Qcells | Q.TRON BLK M-G2+ 440 W | 22.0% |

Hi-MO 5m 425 W | 21.8% | |

Twinplus X Series 420 W | 21.51% | |

21.5% | ||

Sunspark | SST7F54M(H) 415 W | 21.30% |

21.1% | ||

ZXM6-NH132 Series 420W | 21.03% | |

United Renewable Energy Co., Ltd. | Peach FBK410MFG 410 W | 21% |

HC 108 410W | 20.97% | |

DNA-108-BF10-410 410 W | 20.96% | |

XG BK Series - Black Max 280 W | 20.86% | |

Arkra Series 415 W | 20.78% | |

Gamma Series 415 W | 20.7% | |

Solstice 440 W | 20.5% | |

PowerX 400 W | 20.5% | |

Freedom Forever | 400 W module | 20.48 |

19.9% |

Solar panel efficiency FAQ

Catherine is the Written Content Manager at SolarReviews, where she has been at the forefront of researching and reporting on the solar industry for five years. She leads a dynamic team in producing informative and engaging content on residential solar to help homeowners make informed decisions about investing in solar panels. Catherine’s expertise has garnered attention from leading industry publications, with her work being featured in Sola...

Learn more about Catherine Lane